|

|

|

|

|

|

|

|

Sorry

for the poor quality translation. source here

Rossi's

power-cell. (RPC ���)

By early 2012, the

structure of the RPC gradually took their full functional form, as a kind of

unit, suitable for a wide application in many sectors of the economy. Rossi

proved the reality of LENR energy on an industrial scale to produce, and now it

is time for the intellectual, operational and financial resources of the Society

for the widespread use of this opportunity to connect. Suddenly a broad front

of the work appeared in four areas: academic science, experimental physics,

engineering applications, speculative commercial direction.

|

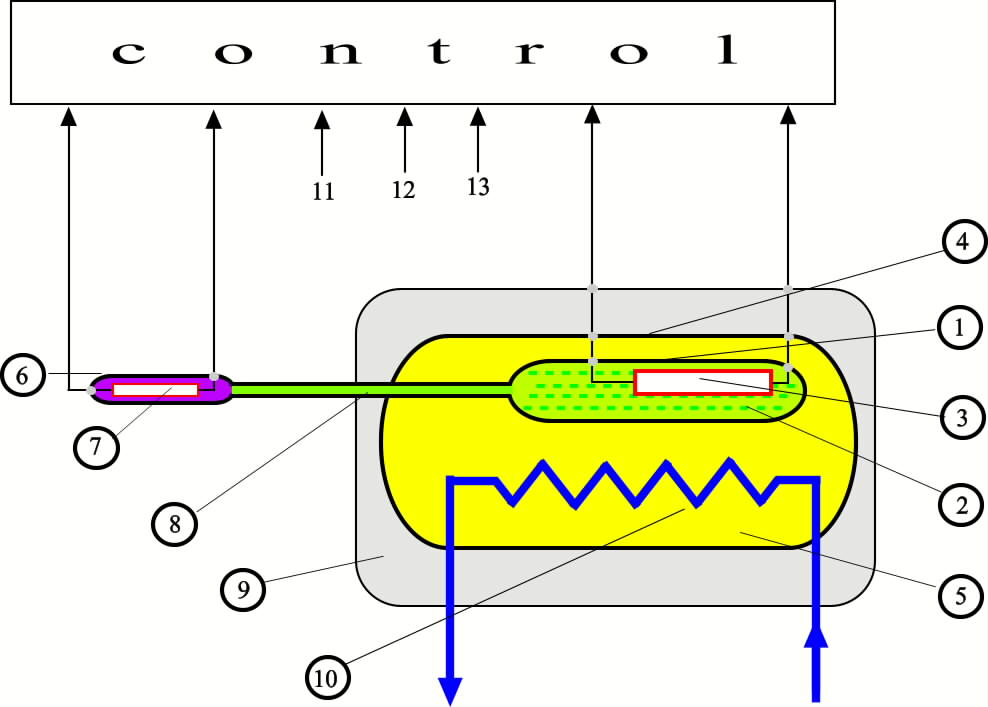

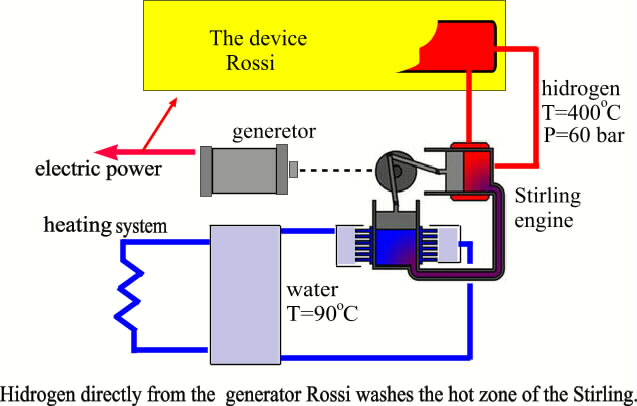

The picture shows a

generalized diagram of the heat generator Rossi, a configuration with a series

of necessary and sufficient components for the operation of the device. |

fig. 1. |

Such conditions are

hydrides of some metals just like Magnesium hydride. One cubic centimeter of

this powder contains hydrogen by weight and a half times more than its

contained the same amount of liquid hydrogen. However hydride of iron-titanium

alloy such as dissociated at temperatures from 320 to 370 K with a low heat of

formation. The tube (8) connects the regenerator of hydrogen with a closed

reactor of thermal insulation (9). The selection of heat takes place through

the heat exchanger (10) from where there is the coolant in the form of water or

superheated steam. Device control and management receives information from the

temperature and pressure sensors. It maintains the heat of the reactor at the

desired level by controlling the temperature of the regenerator of hydrogen.

The principle of operation.

The scientists in the chemical catalysis, and employs a lot of detail

with the nickel-hydrogen system. They are well known, with processes at the

interface between solid and gaseous phases, such as:

- Dissociative chemisorption of hydrogen molecules on

metal surfaces,

- Dissociation of the adsorbed hydrogen atoms into protons

and electrons,

- Proton dissolution of atomic hydrogen in the crystal

lattice of nickel with the transition of an electron in the conduction band of

hydrogen in the metal.

Written many articles on this topic, for example here or here.

The question is why

the researchers did not notice the anomalous heat generation in their working

patterns? Maybe because they deal with two-dimensional structures, more

sophisticated, but the surfaces. And no one before and Rossi Piantelli not

kalorimetriert the nickel nanopowders under considerable pressure at a high

temperature in a hydrogen atmosphere. Here is just nanopowders, apparently, is

the key. The large surface section between the two phases has led to a

transition from quantity to quality - the start of the heat released

commercially. It turned out that the hydrogen that diffuses through the nickel

grid of dismissal of an electron, has a non-zero probability to penetrate the

core of an atom of nickel. In implementing this probability is LENR - reaction,

accompanied by a large release of energy. Modern science has to deny recently

accompanied the possibility of LENR processes by transmutation of energy

release, and not able to explain clearly the physical nature of the phenomenon.

(Here), but this fact should not prevent the introduction a new efficient heat

source, and the ambiguity of the combustion process does not interfere with

people thousands of years, the use of pyres.

Thus, the more hydrogen

atoms is in the lattice of nickel, realizes the more the probability of

absorption of the proton nucleus of nickel. The concentration of hydrogen

protons in the crystal lattice of the larger, the higher the temperature in the

reactor, the higher the hydrogen pressure, and the more developed the interface

between the gas and the metal crystals. The easiest way to manage the reactor

change, the gas pressure. What has been implemented by introducing in the

device node of the regenerator of hydrogen. It should be emphasized that the

emergency situation that can not be to "accelerate" the process of

heat in the reactor warden occur: during the heating of the specimen sintering

or melting will occur the nanopowder, which leads to a decrease in the

concentration of protons in the crystals .

Operational

quality.

Rossi

generator designed to generate heat energy, it runs on the controller and

allows you to implement custom schedule of heat. The device is connected to the

network, which in operation continuously uses a small amount of electricity to

power the controller and the heating element (7) of the regenerator. Greater

consumption of electricity is required for the initial start-up device. In this

case additionally works fairly strong the heater (3) of the reactor. He

predestined to heat the entire volume of the reactor to operating temperature

and warming to hold until creates diffusing into the nickel crystals hydrogen,

a proton concentration in order to initiate the exothermic reaction. It is

noteworthy that shown for the two-circuit heat transfer, as in the figure, the

power consumption of starting-up phase is substantially less than for

single-circuit, since the heat is not flushing away through the coolant, while

the reactor heated.

Thus, the specific

nature of the heat source at the generator Rossi a slow start after the break,

a relatively shallow level of power control and the slow change of the current

value of the thermal power released. However, these drawbacks are insignificant

in comparison with such dignity, such as an extremely low cost of energy

produced.

Place of RPC

on energy sources.

Generator Rossi, of

course, can be used for space heating as a local heat source, but much better

to treat it as a tool for collaborative production of electricity and heat (the

principle of Cogeneration). In this respect interesting to compare it to other

heat sources that are used to generate electricity. Currently, the most

important technical tool for converting thermal energy into electricity by a

turbine-generator efficiency and the turbine generator and other steam engine

depends mainly on the parameters of the steam at the inlet of the turbine.

|

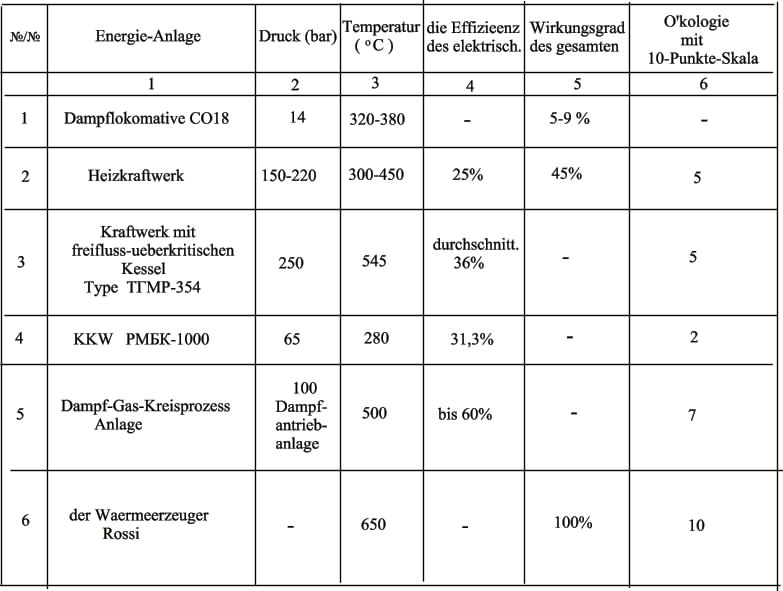

The following table

can be compared, is the area in which these parameters with the use of thermal

energy in the various technical systems. The same data are in the graph of the

phase diagram of water shown. Some clarifications on the points table. A significant

proportion of the electricity in the world produce thermal power plants.

Despite the fact that the steam parameters have come far in the supercritical

region of the phase diagram of water and the formula for the Carnot promises

good efficiency (paragraph 3 - **), the average efficiency of the Russian power

plant would be about 36%. This is due to the fact that all the heat of

vaporization (2260 kJ / kg), which is released into the condenser, it is

necessary, in cooling towers or cooling pools to be dissipated. In Russia, the

practice of building district heating plant (** item 2) was developed. Due to

some reduction in efficiency, it managed to increase the water temperature from

the external circuit to a level (120 - 140 degrees). This made it possible to

transfer the hot water over long distances for the heating of the surrounding

residential areas. |

fig. 2. |

|

In the West, went the

other direction. Steam-gas cycle process (Item 5 - **) separates thermal energy

that is released when fuel utilization in two parts - a gas turbine and steam

turbine. The result was a phenomenal increase in the efficiency of the unit,

almost doubled (from 36 to 60%). This is explained by the fact that a wasteful

process of heat transfer through a two-phase heat transfer medium (water) used

only in the last stage of the process. In other words, the amount of evaporated

water per kilogram of burned fuel in a steam-gas process is about three times

smaller. Against this

background, looks extremely pale, the parameters of the coolant in nuclear

power plants (Item 4 - **) - the most common reactor type RBMK-1000. Water -

water two-circuit system, and the need for frequent replacement of the fuel

rods in the work unit, which are connected to the technological penetration

into the volume of the primary circuit, led (bar 65) to lower operating pressure

and temperature (280 degrees.). Reproduced in the official 31.3% efficiency is

not always fully taken into account energy expended on the station's own needs.

The use of "junk" heat for the plant is not possible, because of its

remote location. The heat generator Rossi (item 6 - **) allows the coolant to

650 degrees. C heat, while the pressure and only to the strength and heat

resistance of the heat exchanger. |

fig. 3. |

Generally in the

energy sector, despite the fact that cleaner burning fuel in a closed space in

the position of the heating boiler design to very high temperatures, can not

penetrate far into the supercritical range of the phase diagram of water. About

Critical fluid acquires new properties, in particular, it is chemically

aggressive. For example, in Iceland, to extract the geothermal energy in the

volcanic area, drilled deep into more than two miles. The resulting fluid

having a temperature of 1100 degrees C corroded pipes and heat exchanger made

of stainless steel. In the column of Table 6.5 of the overall efficiency of RPC

was set to 100%. This is due to the fact that the local device on the principle

of combined heat and power (CHP - Cogeneration), that operates heat, which is

not used to generate electricity, used for heating or air conditioning.

With all favorable

settings of the thermal generator Rossi laurels of victory between the energy

sources is still part of the solar and wind energy - it does not cause thermal

pollution.

The type

of heat-elimination device

Apart

from the auxiliary details, you can look at the heat source Rossi as fuel

element. It is characterized by a well-defined density of volumetric power

output (W / cm ³), geometric shape, which determines the transport of heat from

the working volume and surface area through which heat causes in the

refrigerator. The closest analogue to the physical device is considered a fuel

rod that works on all types of nuclear reactors. It is useful to compare these

two devices.

The

volumetric energy release. Fuel rod in the form of a long tube with a

diameter 1.9 mm is -13.5 bar in the flow of the cooling water with the

parameters of 65, disposed 280 degrees C (for RBMK-1000). Data for its energy

performance are well known: volume up to 450 W / cm, linear 17 kW per meter of

pipe and heat flux 0.6 MW per square meter of surface heat transfer. While no

detailed data for RPC, from the statement that the internal medium of the unit

(molten salt) can can exceed 650 degrees C (here), we conclude that the energy

level of RPC same magnitude as the fuel rod has. "... Has successfully

completed its PDGT scientific, technological and engineering Necessary steps to

sustain such a reaction with results Exceeding a COP of 20 and with

temperatures exceed 650 degrees Celsius capable to ..."

The

energy source. The fuel element of the reactor, the forced splitting

of uranium 235 takes place in the force field of thermal neutrons. The process

has the statistical and cascade-condition, the average energy of 202.5 MeV for

the decay of a nucleus. The RPC is the cold fusion reaction of hydrogen with

one proton nucleus of an atom of nickel (LENR process) assume will be achieved

by, releasing energy that accompanies the nuclear scale. One mole of nickel

makes about 23 000 kWh of thermal energy.

The temperature

distribution in the structure. Fuel element operates in a very tight operation. The

tablets of uranium dioxide have low thermal conductivity, there is a

significant temperature gradient in the radial direction: 1600 - 1900 °. C on

the axis of the tube, on the surface of the tablet, respectively, 470 -900

degrees, further, difference between the pills and the cladding, the falling on

the pan 20 degrees, and finally, 350 degrees. on the surface of the element. To

increase the thermal conductivity of the fuel element, is pumped into the tube

helium, the pressure in operation is up to 80 bar to 100. In operating pressure

can be more enhanced in consequence of the accumulation of gaseous

decomposition products. Solid products of nuclear reactions (heavy uranium atom

splits into two lighter) apart span the tube of the fuel element so that it is

unsuitable for further use, long before the complete combustion of the fuel.

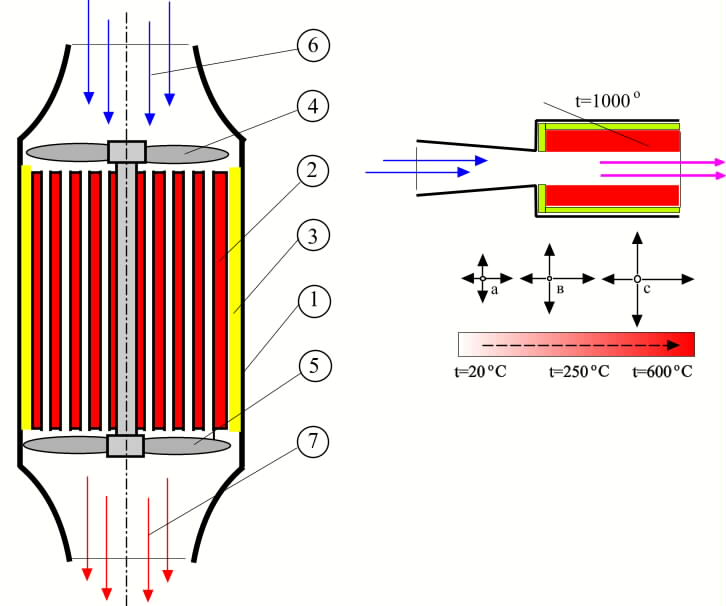

Sun Defcalion GT features to its site, the 21-page specification

Hyperion their

developments. The reactor core - a cylinder with a diameter of 4 cm and 10 cm

long, with a volume of about 125 cubic centimeters. Loose nickel powder in a

hydrogen atmosphere at elevated pressure. With high throughput, and the thermal

conductivity, hydrogen can successfully the heat to the inner surface of the

structure transmitted without areas of local overheating.

The

shape of the energy excretion. The decay of uranium-235 nucleus

into two unequal parts occurs in the seizure of the nucleus of a neutron. The

method is probabilistic in nature. In the fission products are up to 300 other

unstable isotopes of different substances, from Z = 30 (zinc) to Z = 64

(gadolinium) is to excite the cascade of further nuclear reactions take the

tails of these decays may years. Hundreds of types of nuclear reactions are

accompanied by all kinds of radiation with very different energies. In the RPC,

the processes are more monosyllabic - produced only two or three stable

isotopes, energy is in the form of soft X-rays (less than 150 keV) are released

and transferred directly to the nickel lattice.

Managing

the process. Uranium 235, one of the few elements that can sustain

a chain reaction of nuclear fission. Fuel can only work in an environment of a

nuclear reactor. He needs a force field of thermal neutrons, produced jointly

by all the modules, regulator and balance rods and other parts of the reactor

design. Uranium-235 responds to the need on the threshold level of criticality

for 10 ^ -3 seconds (time constant) and for the stable operation of the reactor

that all coefficient of reactivity were negative. For RPC specific heat is

determined by the concentration of hydrogen protons in the nickel lattice. Time

constant of the process is determined by the rate of diffusion of hydrogen in

the solid phase, ie, not milliseconds, both for the fuel, but minutes and tens

of minutes. From here, manageability, and reliability of the device by Rossi.

The

scalability and applicability. A fuel assembly is designed to

work in the construction of a nuclear reactor, an isolated operation of this

device is not in question. For RPC is present tube design is not the limit

seems possible film structures and a massive volume with channels for the

cooling liquid. Accordingly, and the wide field of applications - from cell

phones to large turbines.

Ecology. Used nuclear fuel,

due to the residual long-lived radioactive isotopes decay processes, must be

isolated for many months in the pool, and suspend and during the subsequent dry

storage of active ventilation. It is cheaper to bury this stuff in the rocks of

the alluvial fan in the Arctic Ocean at the mouth of the Mackenzie River. RPC

at the minimum protection does not radiate, does not accumulate unstable

isotopes are fully recycled and regenerated in a simple chemical process.

Place in

the middle of LENR processes.

There are some

spectacular effects, such phenomena Schoulders, Vachaeva, Adamenko, Ushirenko

which accompany the transmutation of elements, intense energy release and the

involvement of charge-cluster phenomena. However, unexpectedly moved forward,

the process of nuclear interaction on the resonance frequency of the hydrogen

protons in the crystal lattice of nickel.

Yes, based on the effect of Fleischmann-Pons' an installation by Andrea Rossi

proved to be more logical techno to get the heat on an industrial scale. But,

of course, that after removing the tacit LENR-taboo around the world unfolds

and opens itself to finance a broad front of work. And then developments KEN

'SHOULDERS', its charge-clusters, researchers will lead to the possibility of

direct conversion of nuclear energy into electricity. (Here) on his Vachaev

"Energonive" probably many kilowatts of electricity gets turned off

successfully, and radionuclides. (here) to the promise of Adamenko developments

in his laboratory (proton 21) to obtain the industrial extra heavy stable

elements. (here) In general, any transmutation of matter transforming nuclei of

one element into another, with different composition of the nucleon, and appear

at the same deficiency or excess charges, can, of course, is to be converted

into an electric current, you only need a to find suitable way.

Only four metals in

nature - iron, nickel, palladium and platinum have the ability to dissociation

of adsorbed hydrogen into protons and electrons following proton penetration

into the crystal lattice. The effect of Fleischmann-Pons' and open to the

palladium and implemented on an industrial scale on nickel are not excluded

from consideration as a promising source of boundless energy and also iron.

The

specific implementation of the system.

The first trades, the

inventor A. Rossi can be presented at the shows instead of the existing

laboratory models are estimated, - installation of experimental physicists are

always structurally redundant, depending on short-term opportunities and local

artists. Nevertheless, they held a demonstration to investors to convince them

to invest heavily in design, engineering products. (In particular, Decalion

Green Technologies released a series of devices, "Hyperion" hier. ()

only significance to the assembly are "megawatt, he" returned from

the small blocks - having Rossi, not enough time, instinctively clings to the

found earlier decision.

Once falling into the

hands of professionals in the technology, the idea of guarding the missing

components, such as how regenerator of hydrogen, instead of the difficult and

dangerous to the operation of the hydrogen balloon. Similarly, will be

assessed, such illogical practice, how much of the heat that is used for

formatting the preparation transferred directly to the consumer. Next, more

efficient units will not be recruited from smaller structural units. And of course

the first thing that user to the RPC system, a device for generating

electricity.

|

As an unknown still

quite efficient method for the direct conversion of nuclear energy into

electrical energy, and Rossi generator is a heat source, power obtained with a

more or less acceptable efficiency is possible only via an intermediate

transfer of heat energy into mechanical energy. Such a transformation takes

place during the expansion of the hot gas (pressure medium) in a particular

structure that the ability to change its internal volume must, for example in a

cylinder or a turbine. As a

working fluid (working mass) can emerge: 1. First The same hydrogen that participates in

the LENR process of the generator Rossi. 2. Second Air or another gas, heated by contact

with hot designs RPC. 3. Third The liquid is vaporized and superheated

in the heat exchanger, which is in thermal contact with the construction of the

reactor (of water vapor other liquids). |

fig. 4. |

|

In accordance with

the principle of Carnot efficiency of this transformation is larger the higher

the temperature difference between the working fluid at the beginning and end

of the process. On the first point, this difference is the greatest, example of

this principle are shown using the Stirling engine in Figure 3. The second point is

illustrated in Figure 4. The principle of Staustrahldüse and the ramjet could

be fully extended to the heat source Rossi. The air is warmed up along the

heated surface, expands, pressure and axial velocity component increases. As it

happens, the plan says the right. During the heating of the gas linear

velocities of the molecules is proportional to grow in all directions. (Vector

diagrams a, b, c) molecules, which move to the left, meet in the cooler layers

of gas, stuck in them. They give their energy to the heating of these portions

of the gas. Compensate in this case the vertical offset vectors, and preferably

the right direction. |

fig. 5. |

And this is the main

disadvantage inherent in the method using a two-phase refrigerant. In the

mechanical work into electrical energy, and therefore only the thermal energy

will be transferred, stored in the superheated steam, but provide a significant

heat of vaporization must be completely in the refrigerator. In the case of

water, its temperature is at the outlet of the condenser cooling circuit is not

more than 50 - to provide 30 degree - 60 degree, and the input capacitor must

not hot water 20th This relationship makes little interest to utilize waste

heat for heating purposes, and provided nearly impossible for air conditioning.

This can be by the fluids to help with higher boiling points, but it decreases

the efficiency of power generation.

If RPC is used

without a power generator, only a heat source, then it would be nice if the

device does not provide start-up, or at least operating system power supply. Such

possibilities are, for example, is currently in bismuth - produced telluric

thermoelectric module (HZ-20 Thermoelectric Module

http://www.hi-z.com/hz20.php), with dimensions of 75 * 75 * 5 mm in temperature

difference of 200 degrees produces 20 watts of electricity with an efficiency

of 4.5%.

Heating

and air conditioning.

A. Parshev in his

essay "Why Russia is not America" is wrong, "that our country is

not competitive due to the harsh climate in its territory who spent too many

resources on capital construction and heat for heating buildings. Much more

people around the world suffer from the heat, - the need for greater cold, cold

production expensive - the need for refrigeration is wider, cold production is

more expensive would, even in our northern border of the 3-4 months of the year

does not hurt to air. -conditioners operate, however, food refrigerator in

Russian families "eats" a third to half of the current. Three billion

of "Southerners" could be very substantial increase in energy

consumption, they would have to "human" in terms of temperature and

humidity in the home and in the workplace.

Realized with current

in sufficient quantities, no problems with heating, air conditioning, it is

also easy for a 1000 kW cooling capacity with modern vapor-compression machines

(cooling coefficient I = 3,0) have to spend about 300 kW power. The cold

therebetween can be obtained with a heat source - it is widely used by

absorption chillers. They have not so large cooling rate (I = 1.35), and the

cold water temperature at the output of 2 to 5 degrees. C, but they are

environmentally friendly, no noise, reliable and consume almost no costly power.

Individual user weight is calculated on the RPC needs, usually at the same time

and heat and cold, and electricity. The relationship between the carrier of

energy during the day and can vary depending on the season. To produce the

complex heating, cooling and electricity - is brought into modern terms

trigeneration (trigeneration) is engaged.

| The

main innovation in the field of energy of the last decade has been the practice

of recognizing the rights of small businesses and even occur to some people in

the market for power generation. Here the priority is quite heard of Germany.

Technically it is possible to leave with the advent of network interface

devices, the power system network downstream, with internal power supply

subject. Such a device is relatively inexpensive because of its mass

production, consideration of energy allows the network, as well as the impact

energy to the network when you turn on the internal generation capacity. At the

same time not only commercial, dissolved, but all the technical issues:

coordination with the external frequency, phase, amplitude, and higher

harmonics. This is achieved by the so-called direct current use

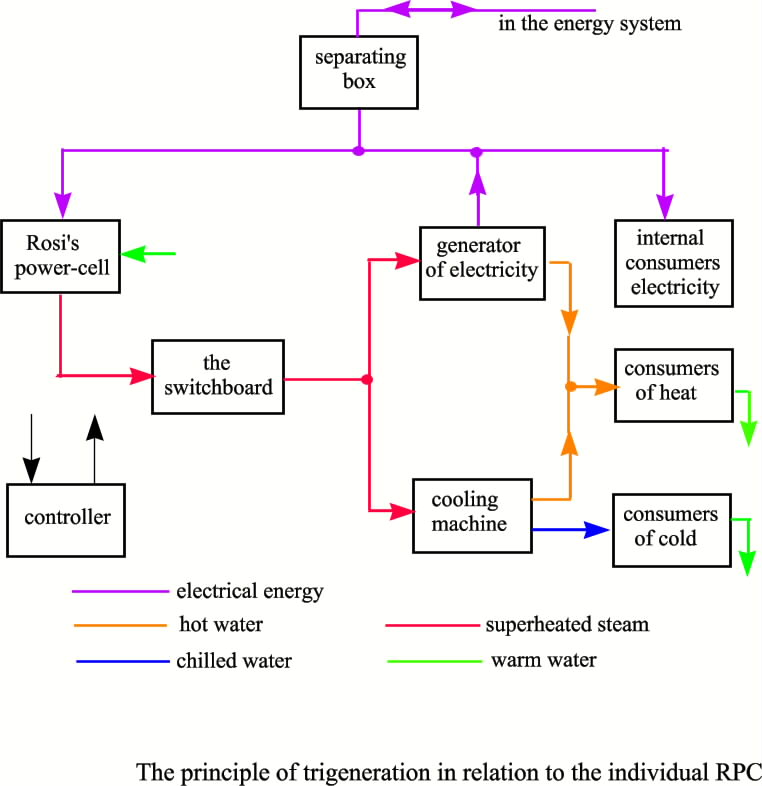

Figure 6 shows a

possible use of each heat generator Rossi in the concept of three generations

and mutual (open) connection to the grid. The thermal generator produces

superheated steam at a temperature of 200 to 300 degrees, which is distributed

in a certain ratio between the generator of electricity and cooler. With some

of the energy in the production of electricity and the production of cold, the

heat transfer is still enough energy to be used for space heating and hot water

are. Managing the device controller to optimize the process to the level of

energy RPC and redistribution of the primary coolant between the radiator and

generator according to the current needs of the user and the existing

electricity tariffs in the energy system. Thus, heat and cold, used according

to the necessity and power generation, in fact, it is possible to obtain the

final performance of the system en bloc to one hundred percent. |

fig. 6. |

The main advantage of

the new technology is the production of energy on-site consumption - no calorie

is not in vain, will not spread into the surrounding space. Forced past such

thing as "waste heat", "inadequate heat," which are now

power plants and nuclear power dissipated in a cooling tower or disperse into

natural pools, because the heat can not be sold to the consumer. Sun Balakovo

nuclear power plant has six units of 950 megawatts and produces 3000 x 6 = 18

000 megawatts of heat, many of which are released into the pond. The area of

??this never frozen, man-made sea is 24 square kilometers. (Look Vikipedija)

There are other applications,

RPC, for example, the reversibility of Stirling and the inclusion in the scheme

of mass storage (1 to 2 cubic meters) for the cold fluid from the system, a

separate cooling unit are excluded. In the meantime, everyone will be difficult

to implement these systems, while the Stirling engines are expensive and not

assimilated a large scale, small turbines have to learn to make from scratch on

new, even with back-and-piston steam engines. Meanwhile, at a favorable

development of the situation Rossi builds until the end of the year, a plant

with 1 million units, Deucalion licensed companies - service providers to

acquire the full power for 0.3 million * N units per year.

... 04/11/12

- scope.

- manufacturer.

- chronicle of events.

- References.

![]()